Technology-Based Asset Integrity Assurance

What is Arcus

MANAGEMENT SOLUTION

Productivity Features

Schedule a live demo

What is Arcus?

ARCUS is an innovative Testing, Inspection, Certification and Compliance tool developed over the past 10 years in conjunction with major players within the Oil & Gas and Petrochemical industries. It provides a comprehensive framework to deliver guided inspections of critical assets and inspection disciplines such as Lifting Gear, High Pressure Piping, DROPS and EX inspections to name a few.

The ARCUS framework is built on the following major components:

ARCUS Inspect, ARCUS Server, ARCUS Lite and ARCUS API

COMPONENTS

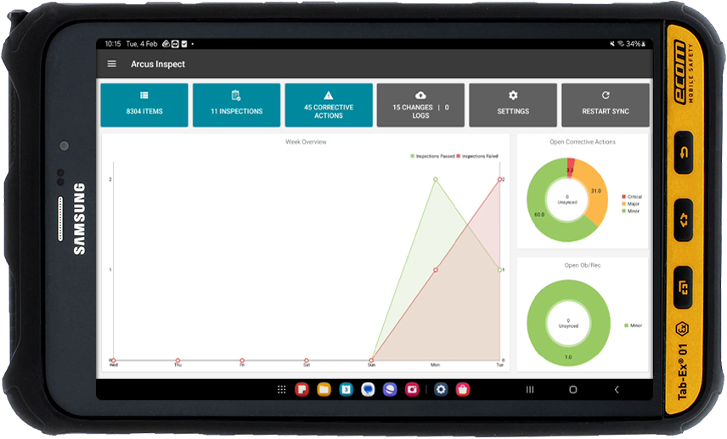

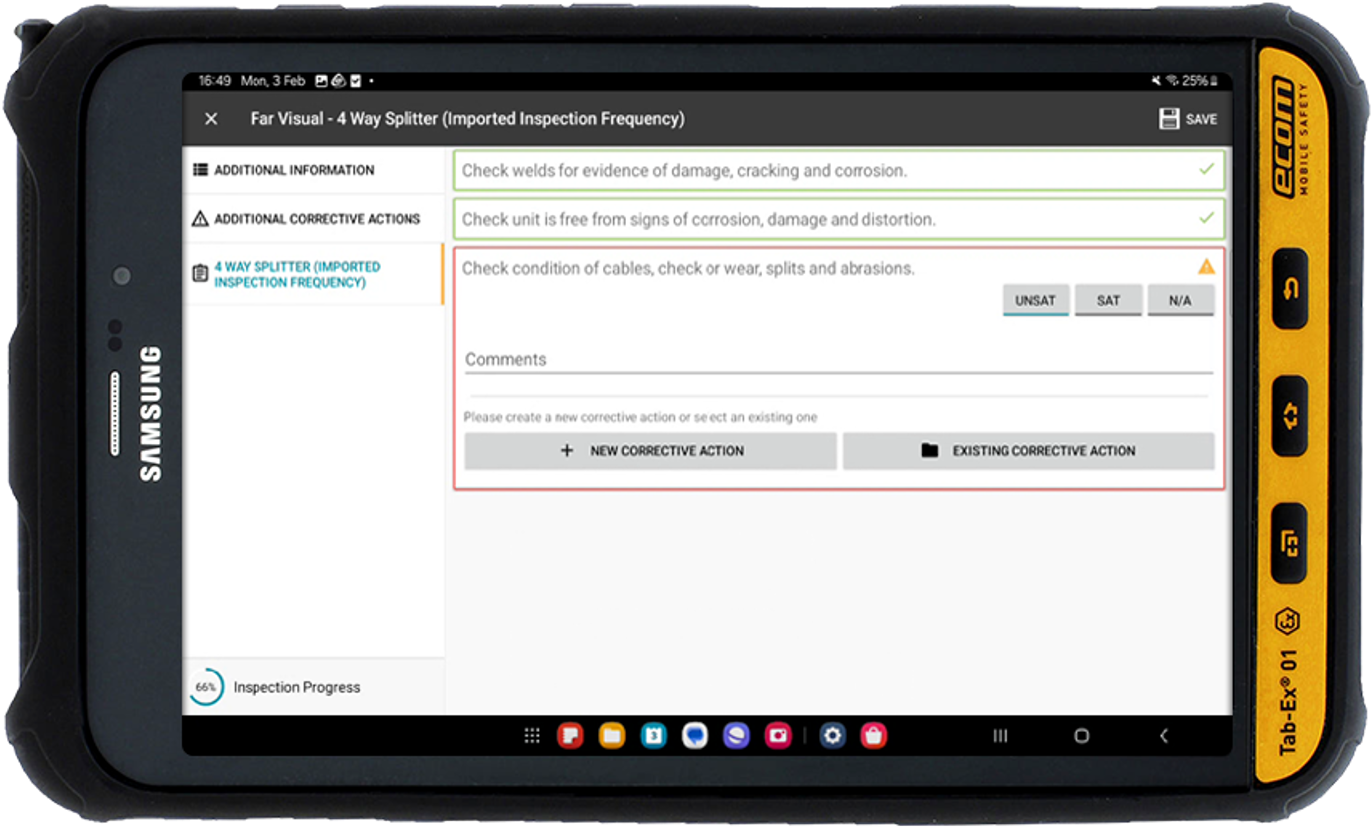

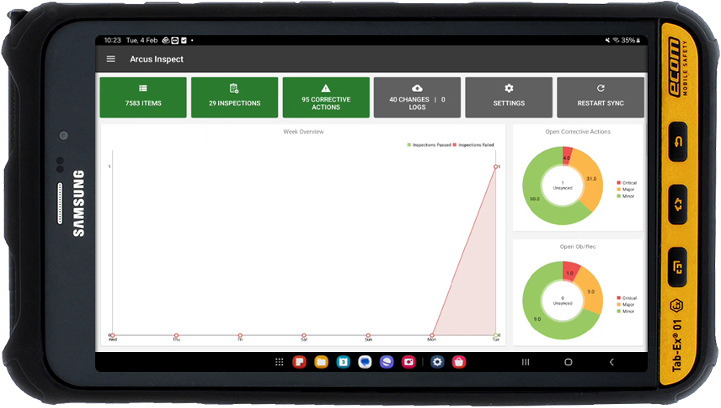

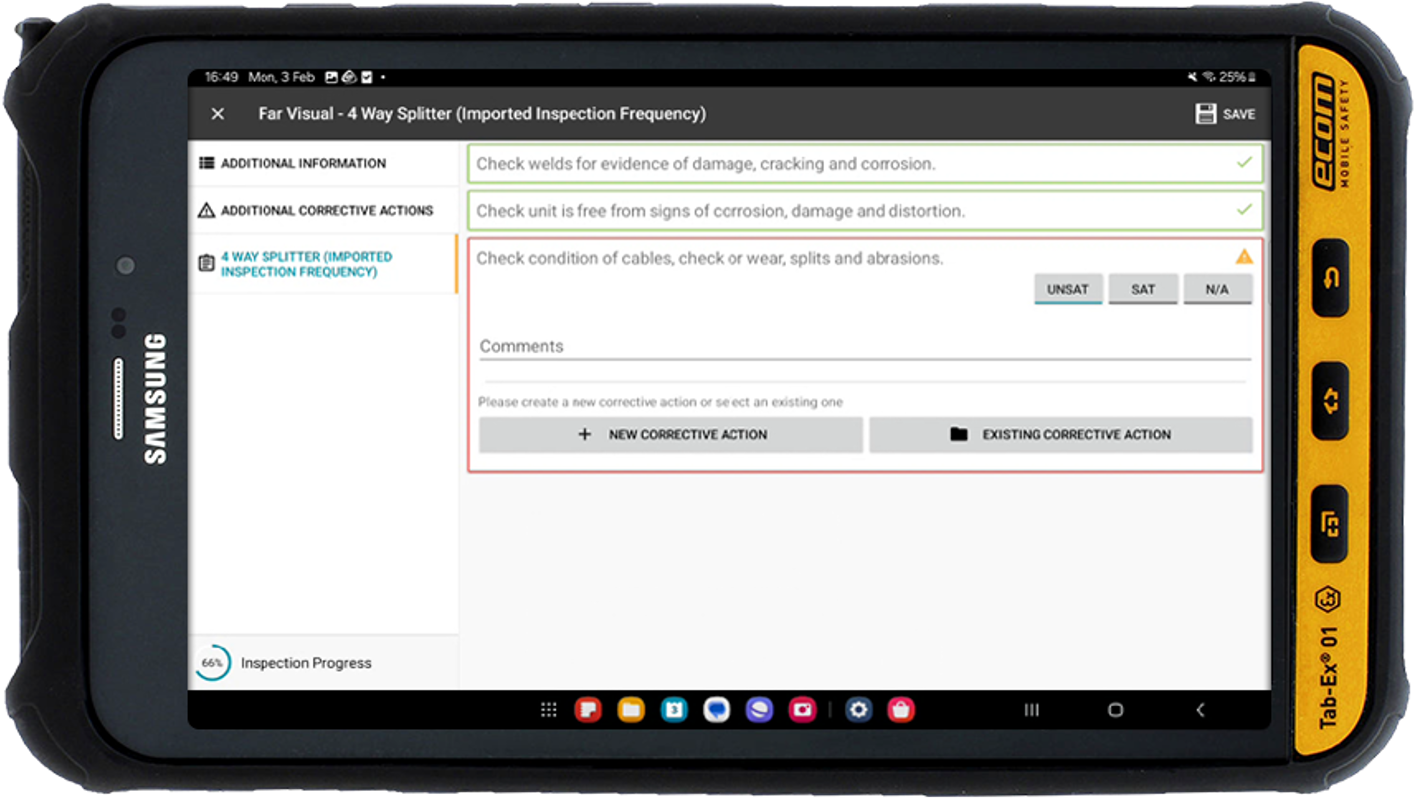

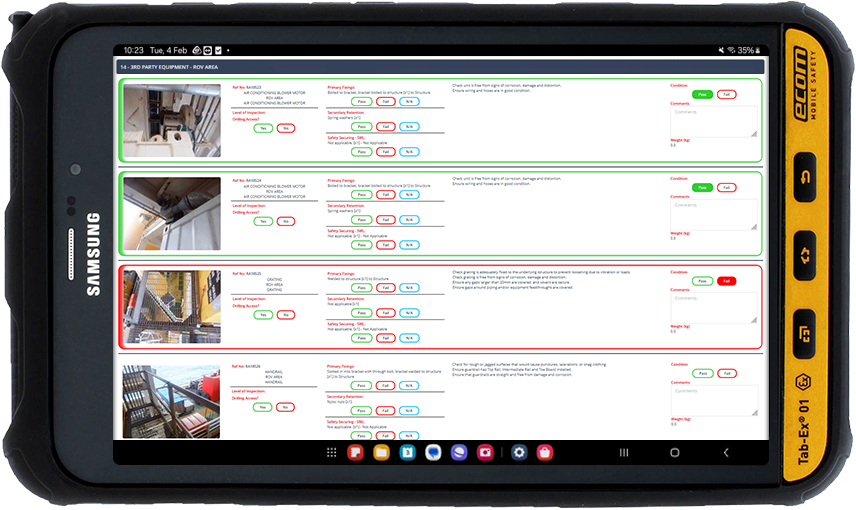

Arcus Inspect

ARCUS Inspect is a tablet-based inspection framework which is adaptable to manage the inspection and certification process for any type of asset. It provides inspectors with a guided inspection prompts using predefined inspection criteria which aligns with published industry inspection standards. Master asset lists for the current inspection are managed and synchronised from head office, along with any historical inspection data. ARCUS Inspect also provides the inspector with the capability of directly raising and centrally managing Corrective Actions from a single interface. Data is continually trickle fed back to head office during the inspection process to allow concurrent tasks such as proof reading, certificate issuance and report generation to make the inspection delivery very efficient.

Dropped Objects Programme

ARCUS DROPS provides the systems that support the management of potential static and dynamic dropped objects on your offshore and onshore assets. With fully integrated control of Corrective Actions, ARCUS DROPS

- Recording of detailed safety securing and retention methods

- Asset scheduling aligns itself with your Preventative Maintenance regime

- Photos help identify assets and are also used to support corrective action resolution and close-out

Lifting Gear Inspections

ARCUS LGI inspections are often conducted in line with LOLER, API, British Standards and other client or regional requirements. Surveys supported by ARCUS LGI cover all types of fixed and loose lifting equipment inspections, including for example:

- Loose lifting equipment, such as slings, shackles, chain blocks, etc.

- Fixed lifting equipment, such as padeyes, beams and other fixed lifting items

- Winches and jibs and cranes

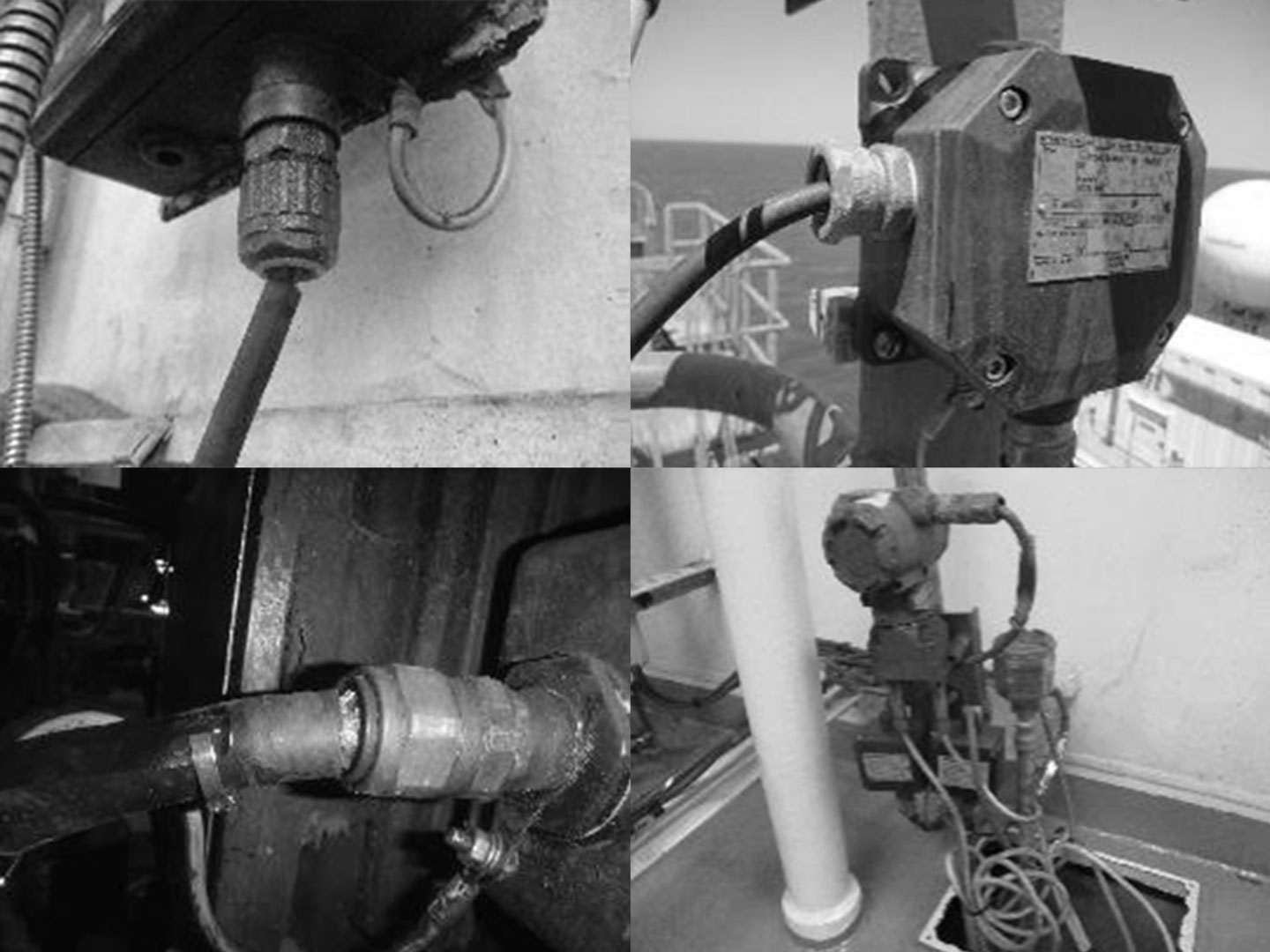

EX

ARCUS EX ensures that electrical equipment used in hazardous areas (where flammable gases or dusts are present) is safe and compliant with relevant standards, preventing explosions and fires.

EX surveys focus on the following areas:

- Hazardous area classification – determining the zones where flammable substances are present.

- Equipment compliance – ensuring that electrical equipment is designed and installed according to relevant standards

- Regular inspections – conducting periodic inspections to ensure that equipment remains safe and functional.

Hose Inspections

The ARCUS-Hose service provides the identification and tagging of hose assets using multiple tags, providing real time reporting of location and condition. Detailed recording of asset details such as manufacturer, length, flange types, purchase date, supplier, wall thickness and tolerance measurements etc. help provide an analytical view to aid preventative maintenance. The pre-defined inspection can then be carried out in line with existing customer PM System.

Bolt Inspections

Regular inspection of bolts and the area surrounding them is imperative to mitigate against corrosion in the harsh environments of the Oil & Gas Industry. The ARCUS-Bolt service identifies the bolts included in the scope of that inspection with a master tag and photographic evidence ensures bolts are inspected. Provides inspection criteria including items such as tap test, torque and visual checking and supports up to 20%/5 year inspection rotation. Colour coding may also be used to provide an immediate visual check of inspection status.

Blowout Preventer Inspections

The ARCUS-BOP service records the identification, journey and maintenance history of sub-assets with a real time audit trail. Using very robust and durable RFID tags to tag BOP sub-assets, tested to 10,000ft depth and several years repeated sub-sea use up to 6 months at a time.

Arcus Server

ARCUS Server is the cloud-based management portal which manages a client’s entire asset and rig estate. It is the central repository for all assets and associated inspection data, metrics, and corrective actions. Securely located in Azure public cloud, data can be deployed in any geographical location worldwide, thereby satisfying any specific data sovereignty needs. Access to the portal is through a secure web portal providing access to all features of ARCUS Inspect, as well as the following major certificate and report generation functionality:

- Efficient and optimised synchronisation of inspection data from ARCUS Inspect directly to head office

- Provides a live view on inspection progress

- Allows simultaneous proof reading and QA by technical staff

- Provides final certification of assets with certificates immediately available to the client

- Final report generation by the technical team

ARCUS Lite

ARCUS Lite is an extension of ARCUS Inspect which gives the client direct access to their asset database to perform routine in-house inspections such as DROPS. This replaces the need for paper-based tick box exercises and gives instant visibility of the progress and effectiveness of ‘In-House’ inspections and vastly simplifies the management of this information. Some other features of the Client Module include:

- Digitisation of regular maintenance tasks

- Daily Reports

- Tools & Assets Aloft

ARCUS API

API interface to provide either push, pull or push/pull integration into a client’s maintenance and asset management systems. Our API securely interfaces into leading ERP solutions such as SAP, Oracle, Maximo, Dynamics etc., providing further data efficiency benefits and instant visibility of asset integrity and inspection processes

PRODUCTION

What are ARCUS’ productivity features?

ARCUS has always been designed from the ground up with harsh and disconnected environments in mind. Although sites quite often have Internet connectivity, ARCUS also provides the ability to deliver comprehensive rig inspections in areas with there is no Internet connectivity. Our innovative approach proven in the field allows multiple tablets to synchronise their data to an on-rig data repository, ensuring the integrity of data is maintained and collated. Collated data can then be synchronised to the ARCUS Server once connectivity is re-established.

ARCUS has been designed in cooperation with a major 3rd party inspection provider for over 10 years and as such exactly aligns itself to highly compliant operational environments. The product is in continual development and some of the other innovative elements of the product include:

The use of Artificial Intelligence

Ensures the most comprehensive completion of inspection data, immediately informing inspectors of incomplete, inconsistent or duplicate d data with the rest of the inspection team. This increases the efficiency of the inspection deliverable and enables the delivery of accurate information, the first time, every time.

Data is always safe

Stored data within the tablet is encrypted, as is the ARCUS Core infrastructure, and data in transit is encrypted using TLS. Data on tablets can also be remotely wiped in the event of loss or theft, ensuring customer data is not compromised. The solution is built on the CIA triad, ensuring Confidentiality, Integrity, and Availability at all times.

We can provide an audit trail of inspection activity

Such as the user performing the inspection as well as verifying geographical location through the use of GPS.

Resource management and scheduling including:

- Tools location tracking & Calibration

- Human Resource Availability, Mobilisation & Capability Management

Management of inspector qualifications, visas, inoculations and capabilities

- Rapid and efficient team deployment

ARCUS Suite of Asset Management Solutions

ARCUS can be tailored and enhanced to your specific industry requirements, but its features include:

Asset Management & Certification

Asset Inspection Frameworks

Dropped Object Surveys

Loose / Heavy Lifting Gear Inspections (LGI)

High Pressure Piping

BOP Surveys

Bespoke Inspection Frameworks

Cloud Based Portal & Reporting

Remote Tablet Based Asset Management and Inspections (Full Offline Support)

Audit Trail and Changelog

3rd Party Integration

Global Support

Testimonials

Provides a technologically innovative solution to completing Inspections in the challenging environments of the Oil & Gas Industry.

Contact

+971 (0)4-326-2822

arcus@askaris.com

Offices

Office 202 Palace Towers 1

PO Box 75971

Dubai Silicon Oasis, Dubai, UAE

Schedule a live demo

Copyright © 2025 Askaris Cyber Security LLC ®